Locker Woven Wire Mesh Applications

Woven wire mesh has a seemingly infinite range of applications. In the domestic environment it is used in many applications for example; tea strainers, flour sieves, coffee filters, fireguards and fly screens.

It is incorporated into many domestic appliances, in filters for motor cars, and is used in the manufacturing processes for floor coverings, chipboard, hardboard and other building materials.

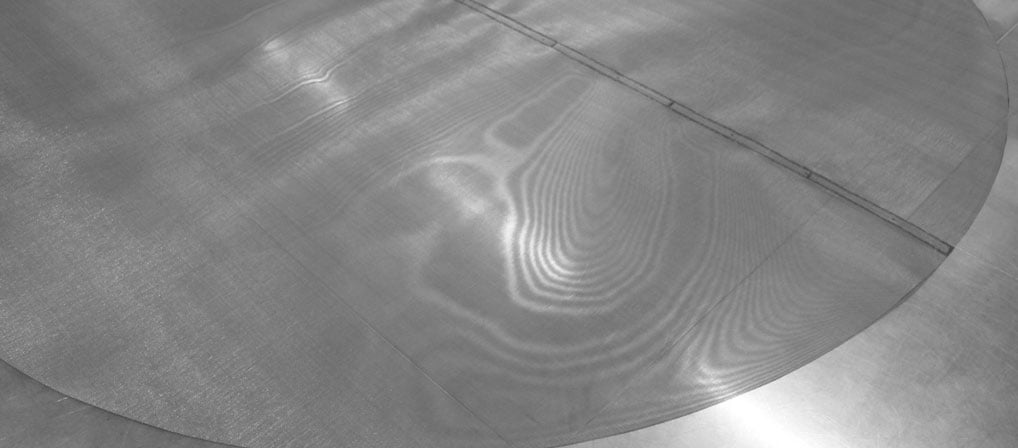

In the industrial environment it has countless applications. As a precision woven product the ability to maintain accuracy of aperture size offers enormous scope for the use of wire mesh as a filtration and screening medium for a variety of particle/fluid/gas separation cleaning and sizing applications.

Wire mesh has wide ranging characteristics, and dependant on the configuration of wire thickness in relation to aperture size, can vary in texture from being as fine, soft and flexible as silk to being as rigid and durable as steel plate. Many of the properties of wire mesh are not available using alternative metal media (such as expanded and perforated metals) or synthetic meshes.

Wire mesh offers many benefits including:

widest range of filtration, from over 6 inch aperture down to 1 micron nominal

high open area/flow rate

closely controlled, accurate apertures

smooth surface; screening surface has no sharp edges, burrs or acute angles

very high temperature tolerance (variable according to metal selected)

usable under high pressure

flexible - ideal for forming rigid concave/convex shapes

control of chemical/acid/corrosion resistance using different metals

special aperture requirements can be met without high tooling costs

high durability

self supporting

suitable as support for less rigid media

stable under tension

weaving process uses no punching or piercing operations that create stress induced weaknesses

point contact only on screened product allows freer screening and reduced blinding

In addition to applications in filtration and separation equipment, woven wire mesh is widely used for:

- Air conditioning systems

- Air filters

- Dishwasher filters

- Noise filters

- Oil filters

- Gas detection services

- Hydraulic systems

- Metering equipment

- Smoke detectors

- Turbines

- Optical lens manufacture

- Acoustics

- Distillation

- Aviation

- Chemistry

- Energy

- Solar engineering

- Lightning strike protection

- Printed circuit boards

- Capacitors

- Hot gas filtration

- Catalysts

- Sugar filtration

- Reinforcement and strengthening

- Ventilation screening

- Radio and micro-wave screening

- Screen printing

- Transportation belts

- Speaker grilles

- Plastic extrusion

- Reinforcement and strengthening

- Ventilation screening

- Radio and micro-wave screening

- Screen printing

- Transportation belts

- Speaker grilles

- Plastic extrusion

- Optical lens manufacture

There can be few industries where wire mesh does not have a part to play, and with the company's wide experience there are few industries that Locker have not supplied.

View information about selected applications of our woven wire mesh:

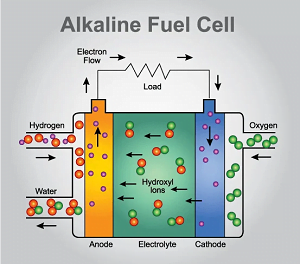

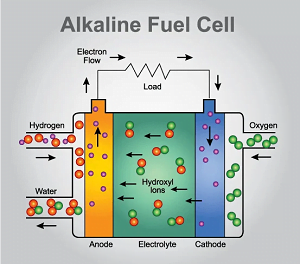

Locker metal mesh is used for a range of fuel cell applications, and can be applied to a wide variety of battery and electrical accumulator processes.

Read more about wire mesh for fuel cells and batteries

Read more about Polymer Filters